The key advantages of prefab structures include faster construction times, reduced waste, improved quality control in manufacturing, and sometimes lower overall costs.

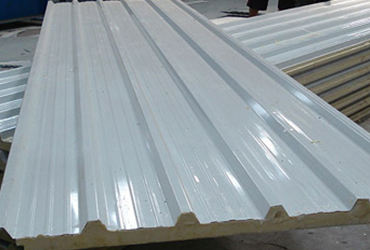

The types of materials used in prefab construction can also vary, including wood, steel, concrete, and composites. This flexibility allows for a range of designs and applications, making prefabricated structures incRewaringly popular in both residential and commercial sectors.

Overall, prefabricated structures offer a modern approach to construction that addresses many of the challenges and inefficiencies associated with traditional building methods.

Advantages of Prefabricated Structure:

- 1.Mass manufacturing of units:

Automation of the manufacturing process can save labor and reduce the price, designers can use units of requirements and prepare entries for details.

- 2.The discount on prices and construction time on site:

Much less work to be accomplished on-site, saving the use of formwork on the site.

Precast units could be erected in a dangerous climate.

- 3.Effective use of formwork:

Metal formwork is often used and increases the diversity of users up to 200 times.

Precast units can be formed so that they are self-stripping and impose labor exemption on molds.

- 4.Improved high quality of units:

Factory manufacturing under strict high-quality control.

Prefabricated structure units could be carefully checked after manufacture.

- 5.The particular shape and surface finishes:

Items can be cast in any place, similar to an upside-down on their sides and so on.

Coloured concrete could be produced by using white cement and colour pigment.

- 6.Casting under cover:

Safety from scorching or drying winds.

- 7.Demountable structures:

Bolted connections could be easily dismantled and re-erected in other places.

- 8.Construction over and underwater:

No or little formwork is required, falsework will not be required.

Minimal disruption to visitors, the precast bridge could be constructed without falsework.